Directional Pads: Fitting Observations

26 Mar 2025

Category:

With ongoing demand for enhanced performance, vehicle manufacturers have designed brake pads for numerous applications that must be mounted directionally. NAPA has followed suit, offering replacement directional pads that meet or exceed the performance of the original equipment.

Directional brake pads are formed differently to traditional brake pads. Technicians must take measures to reduce fitting issues and the effect they’ll have on the vehicle’s performance. Understanding how directional pads function and what issues they’ve been designed to prevent is imperative to minimise customer dissatisfaction.

What Issues Do Directional Pads Alleviate?

As the size and weight of vehicles increase with the requirement of standardised safety features, vehicle manufacturers struggle to eliminate these issues. A braking system on a modern vehicle can take 3 years of research and development, with a focus on reducing NVH (noise, vibration, and harshness). Every vehicle on the road will have been subjected to unique testing to develop the optimal braking system for that vehicle. Focused technology like directional pads further enhance the driver experience.

It could be assumed that advancements like directional pads improve braking performance and thermal efficiency (reducing the build-up and retention of heat), but this isn’t necessarily the case. Instead, directional pads serve two main functions: the reduction of vibration or chatter, and the elimination of brake squeal or noise.

What Should Technicians Be Aware Of?

Manufacturers have various methods for solving NVH. There isn’t a single conventional way a directional pad operates. When deciphering how a directional brake pad should be correctly fitted, technicians need to be aware of the many methods employed by manufacturers.

Chamfer

Brake discs can “pull” standard pads when braking, which can lead to damage, uneven wear, and poor braking performance. Chamfers provide a transitional edge, usually up to 45 degrees. This can either be found on the leading edge of a brake pad or on both edges of the pad.

A chamfer induces even pad wear, reduces noise, and keeps the leading edge of the brake pad from lifting and being pulled away by the brake disc.

When installing brake pads with chamfers, fitters must look out for the angular edge of the friction material. There may be an arrow on the back of the pad when there’s only one chamfer. This arrow indicates the rotation of the disc into the pad. If there’s no arrow, the chamfer should face the leading edge where the pad first contacts the brake disc.

Shims

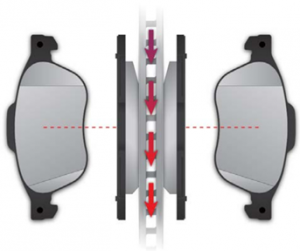

Most brake squeal is caused by oscillation between the pads, caliper, and discs. With rigorous research and development, NAPA Braking has manufactured shims that are fixed onto the rear of each brake pad, helping to locate it correctly within the caliper.

Brake shims add mass to the brake system, dampening vibration in the pad and caliper. They reduce the transmission and amplitude of brake chatter, which is achieved with dampening material bonded to the pad assembly. Shims can also act as a thermal barrier, ensuring even temperatures across the pad for more consistent braking.

Shims Featuring a Half-Moon or Crescent Cutout

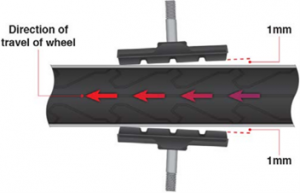

Some shims may feature a half-moon or crescent cutout, which allows the piston to push the brake pad at a desired angle. This reduces noise and supports even pad wear.

Here’s an example of an old-fashioned push bike’s braking system. While the physics are simplified, this demonstrates how the location of the half-moon ensures that the piston touches the pad and forces it against the wheel (or brake disc), halting brake chatter.

The half-moon may be accompanied by an arrow. If not, the cutout will be on the leading edge of the pad. This half-moon must run horizontally across the brake disc and be located on the leading edge to ensure even pad wear and correct force distribution across the pad surface. This reduces pad oscillation and thus prevents noise.

If this type of pad is fitted in the wrong direction, you will likely experience a high-pitched squeal, as the leading edge will contact the disc first.

Directional/Wear Indicators

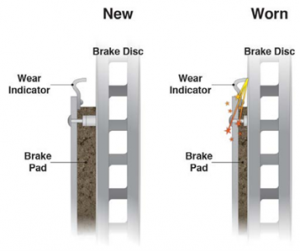

Some brake pads will be installed with wear indicators. These can run electronically, so it’s best to look at how the previous indicator was “plugged in.” A directional pad with an electronic indicator will likely only fit correctly in one direction, so inspect the length and angle of the wear lead.

Alternatively, brake pads can be manufactured with a metal hook attached that will screech when in contact with the brake disc. It should be attached to the leading edge to ensure that the indicator touches the disc before the pad. If the pad is installed backwards, the indicator won’t sound when needed. The driver is more likely to damage the brake disc once their pads wear below the minimum threshold.

What Happens If Directional Pads Are Fitted Incorrectly?

What Happens If Directional Pads Are Fitted Incorrectly?

When a directional brake pad is fitted the wrong way, you lose optimal braking efficiency. This will likely result in the pads squealing when braking. Technicians should always take the time to properly inspect both the pads being removed and the new pads intended for fitting, to identify the correct orientation.

Is there a technical bulletin about [part number]?

If it’s the first time you’ve seen the car, identify how the previous pads were fitted to reverse engineer the process.

If none of these steps clarify how a pad should be fitted, we encourage the technician to look for chamfers, directional grooves, clip-on shims, half-crescent cutouts, and wear indicators. However, if none of these clues are present, contact NAPA Technical or our technical support partners, TechMate. They will be able to advise on the correct fitting procedure for that part number.

A correct fit means your customer’s vehicle won’t face NVH or uneven pad wear. Wrongly fitted parts lead to unhappy customers, the loss of a service bay, and valuable time wasted to diagnose and fix the issue, which all could have been prevented with proper inspection.

Drive Your Braking Know How

Do you have further queries? For in-person support, book a TechMate visit today! Contact the team on 01174 288090. All other technical support is available via our expert NAPA Technical Team on 03333 136597 or email [email protected].

Air Filter Fitment Guide - NFA1587

When installing a new air filter, it’s important to ensure correct fitment is followed. Keep...

Read MoreFuel Filter Fitment Guide - NFF2253

When installing a new fuel filter, it’s important to ensure correct fitment is followed. Keep...

Read MoreFuel Filter Fitment Guide - NFF2272

When installing a new fuel filter, it’s important to ensure correct fitment is followed. Keep...

Read More