How Corrosion Affects Braking

25 Feb 2025

Category:

We know corrosion affects braking, but what’s the chemistry behind it? Corrosion is the natural process of metal deteriorating after a reaction with the environment.

The most common example of this is rust, which forms on the surface of metals when they’ve been exposed to oxygen and moisture. Rust is Hydrated Iron (III) Oxide. Scientifically, this is an electrochemical process that returns metals to a thermodynamic state.

The most common example of this is rust, which forms on the surface of metals when they’ve been exposed to oxygen and moisture. Rust is Hydrated Iron (III) Oxide. Scientifically, this is an electrochemical process that returns metals to a thermodynamic state.

Corrosion is an incredibly costly and dangerous problem. When it’s not prevented, it can cause buildings and bridges to collapse. Medically, it can even be fatal; corroded metallic implants can cause blood poisoning.

In automotive applications, high pollution levels and exposure to de-icing salts make corrosion particularly aggressive. The Society of Automotive Engineers (SAE) estimates the corrosion rate to be similar to marine environments (8.5 µm/year).

Corrosion in Braking

Several braking components are manufactured from cast iron, which offers several benefits. Cast iron has high resistance to distortion and great durability when subjected to different types of forces. It also produces great friction coefficients.

However, cast iron is highly anodic (corrosive). While consumers tend to believe poor quality metal is to blame for corrosion, the high iron content in brake discs is essential for safe and efficient braking.

Brake Discs

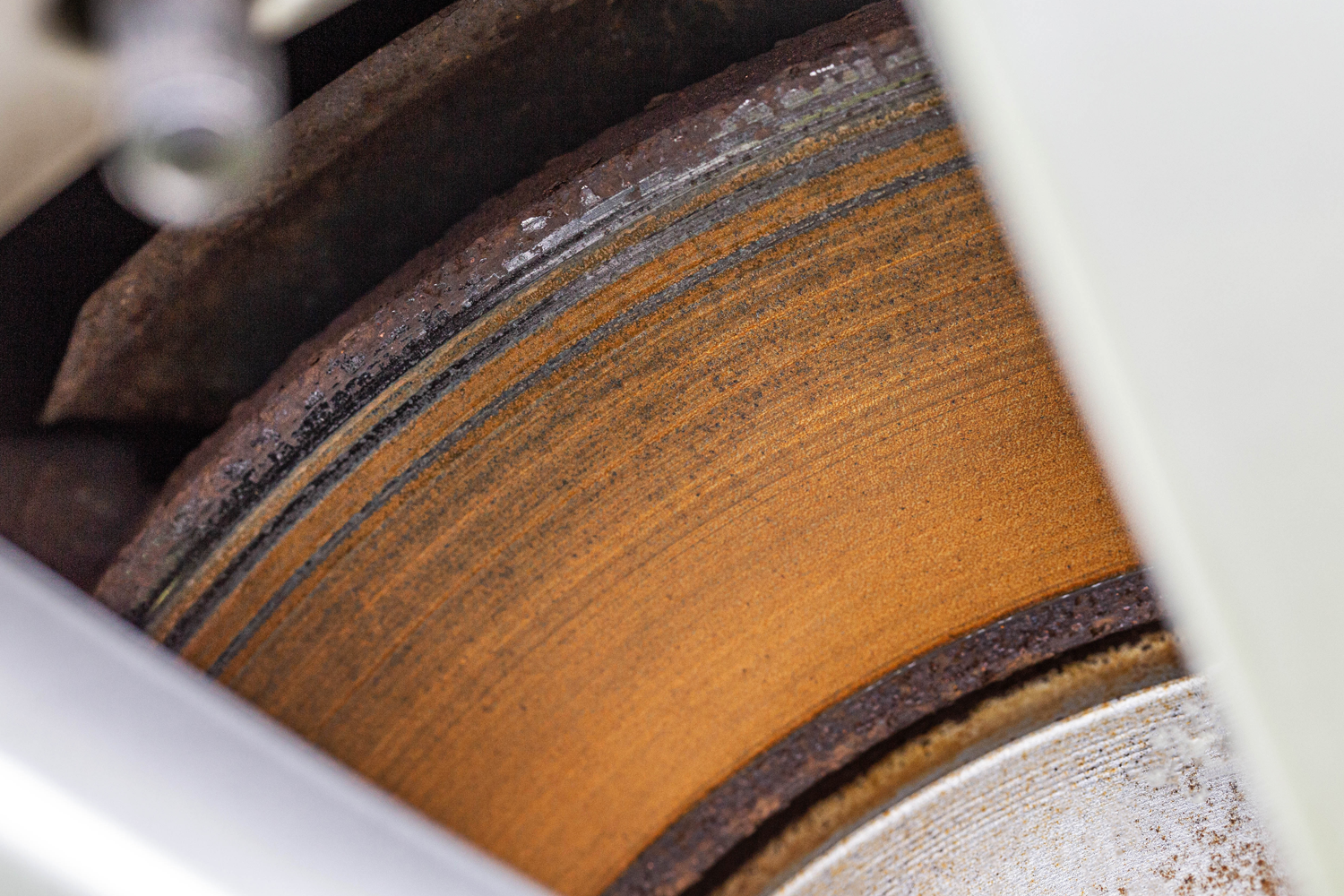

Brake discs corrode faster in high humidity than they do in dry areas. This problem is easy to resolve by applying the brakes when driving, clearing the build-up of corrosion on the surface.

NAPA Braking goes a step further to prevent corrosion of the brake disc by matching the OE design.

The disc edges and hub are coated with a black Onyx Guard anti-rust coating, providing effective protection and a long-lasting smart aesthetic. There’s no coating on the friction surface to ensure the brake pads aren’t contaminated.

Corrosion can still become an issue when the brake discs are left stationary over a long period of time in an area that has over 80% relative humidity.

When corrosion is present on the brake disc surface, NVH (noise, vibration, and harshness) will increase and braking efficiency will worsen. In extreme cases, corrosion adhesion between the disc and pad can occur, leading to severe damage.

Brake Pads

Brake Pads

Brake pads also suffer from corrosion. Corroded backing plates can cause delamination of the friction material.

This could then lead to an increase in NVH, the complete detachment of the friction material from the backing plate, and the loss of braking efficiency and stability.

To protect brake pads from corrosion, NAPA Braking coats the backing plate with an anti-corrosion layer. Removal could leave the backing plate more vulnerable to corrosion.

Other Braking Components

Components surrounding the discs and pads are also prone to corrosion. These components need to be treated to combat the effects of rust and ensure optimal performance.

Effective braking requires free movement, so susceptible contact points must be lubricated with the correct lubricant to aid movement and protect the area.

The lubricant must be able to withstand high temperatures and must be completely metal-free to avoid galvanic corrosion, which will restrict movement. We recommend a petroleum-based brake grease.

Corrosion is further accelerated by certain cleaning methods and detergents used on the surrounding brake areas. Pressure washing can introduce moisture and acidic detergents to tight crevices between the disc and hub, leading to corrosion build-up, misalignment of the disc, and increased NVH (noise, vibration, and harshness).

Caliper slider boots can also become detached from the force of pressure washers, introducing moisture into the cavity; the ensuing corrosion restrict movements. It’s vital that they are removed, inspected, cleaned or replaced, and then lubricated with a hydrophobic (water-repellent) lubricant compatible with the rubber boots.

Although we’re unable to change the braking habits of a consumer, there are steps that can be taken to minimise the development of corrosion. At the point of installation, cleaning the hub surface and protecting with a suitable lubricant will help to prevent corrosion build-up.

NAPA Brake and Clutch Cleaner is a tailor-made, solvent-based blend of hydrocarbon and alcohol, ensuring that even the most stubborn contaminants aren’t immune to its fast-cleaning action.

DRIVE YOUR BRAKING KNOW HOW

Do you have further queries? For in-person support, book a TechMate visit today! Contact the team on 01174 288090. All other technical support is available via our expert NAPA Technical Team on 03333 136597 or email [email protected].

Air Filter Fitment Guide - NFA1587

When installing a new air filter, it’s important to ensure correct fitment is followed. Keep...

Read MoreFuel Filter Fitment Guide - NFF2253

When installing a new fuel filter, it’s important to ensure correct fitment is followed. Keep...

Read MoreFuel Filter Fitment Guide - NFF2272

When installing a new fuel filter, it’s important to ensure correct fitment is followed. Keep...

Read More