Rotating Electrics Fault Diagnosis Guide

30 Oct 2024

Troubleshooting common misdiagnosis problems with Rotating Electrics.

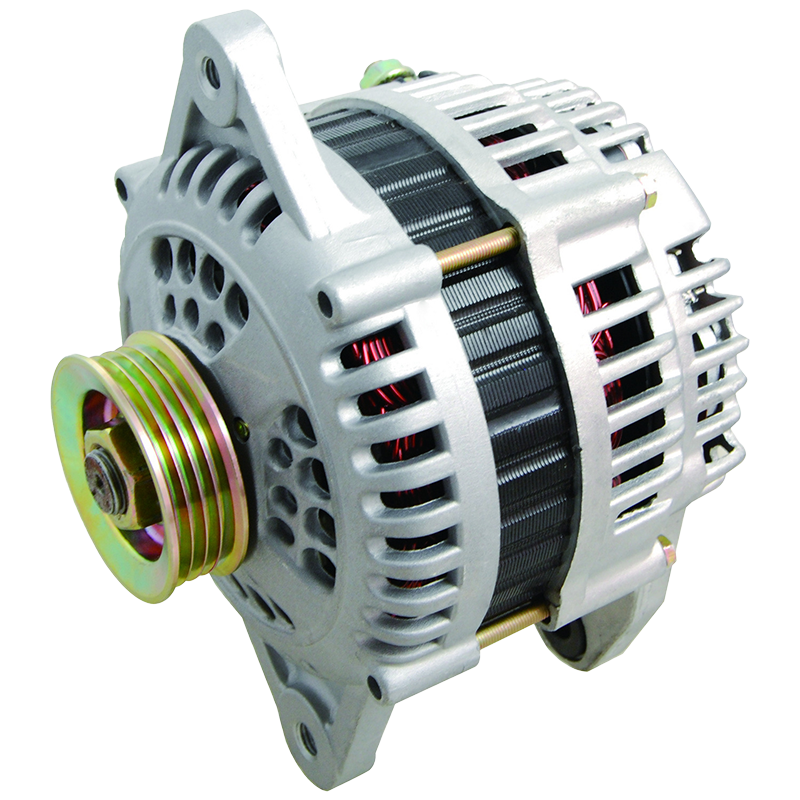

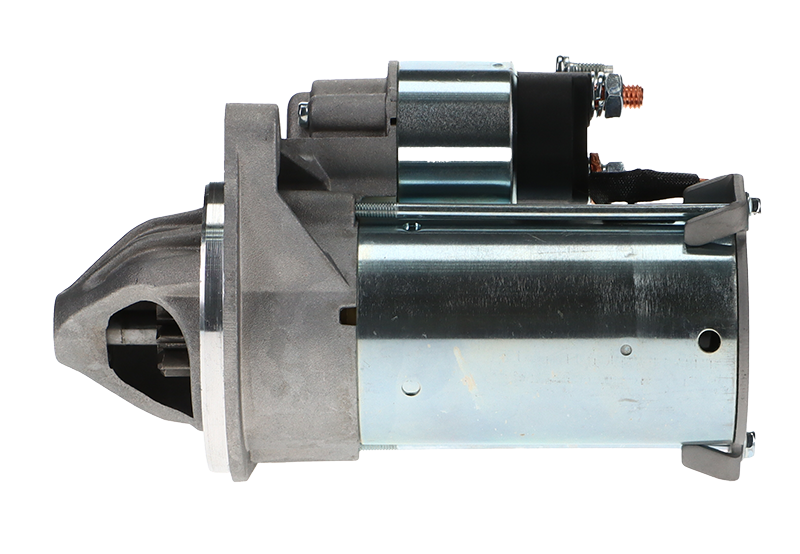

The alternator generates electric current to replace power drawn from the battery and to supply the vehicle’s electrical system. The starter motor uses power from the battery to crank the engine and start the vehicle. This is known as the rotating electrics system.

When there are issues with the power supply, the rotating electrics are often incorrectly blamed.

ALTERNATORS

Today’s modern alternators are often referred to as ’COM’, ‘LIN’ units. They respond to commands and communicate with the vehicle’s computer/ECU/PCM to shut down, wake up, increase output, decrease output, and more.

WHAT IS COMMONLY MISDIAGNOSED AS ALTERNATOR FAILURE?

- Insecure cables and connections, or broken wires.

- A lack of communication between the alternator and the vehicle’s computer, often caused by broken or corroded wiring, especially COM or signal wires.

- Poor battery condition or parasitic load, such as a broken boot or glove box light switch, resulting in a permanently illuminated light when the engine is off.

- Excessive current draw from external sources such as accessory overload.

- Engine management faults. For example, if the alternator is ECU controlled, Ford Smart Charge can be problematic.

- Oil ingress.

SMART CHARGE (LIN, COM TERMINALS)

- Testing a smart charge unit will show fluctuation in voltage, as the required current is drawn from the battery to the ECU, which asks the alternator how much voltage it needs to charge the battery.

- The accurate testing of a smart charge unit requires the correct test equipment.

- A thorough test of the battery should always be performed before fitting a new alternator.

- The ECU must have the fault code cleared before the alternator is connected.

DO I HAVE A SMART ALTERNATOR?

Follow these steps to determine if your vehicle is fitted with a traditional or a smart alternator.

- Locate your vehicle’s battery.

- Ensure all lights, fans, and radios are switched off, then start your engine.

- Take a voltage reading using a voltmeter and note the result.

- Leave the engine running for 5-10 minutes and then take a second voltage reading of the battery.

Traditional Alternator: If your first and second readings are the same, around 14.4V, you have a traditional alternator.

Smart Alternator: If your first reading is around 14.4V but the second reading is lower (around 12.5V–13.5V), you have a smart alternator.

There are many variations in alternators. Some look identical but have a different plug configuration. Always compare the old and new unit before fitting, making sure the pulley is correctly aligned.

Always cross-reference the old unit number from the original alternator to make sure the correct replacement is being fitted.

STARTER MOTORS

WHAT IS COMMONLY MISDIAGNOSED AS STARTER MOTOR FAILURE?

- An ‘overcranked’ vehicle caused by problems with the ignition switch or wiring. Visible signs may include a burning smell and a blue colouring to the teeth.

- Poor connection or a faulty/flat battery. A chattering sound when attempting to start is almost always a low voltage issue.

- Missing spacer brackets. These ensure the starter motor is fitted the perfect distance from the flywheel, but they’re sometimes missed by the installer when refitting.

STARTER MOTOR MYTHBUSTING

- Contrary to popular belief, it is highly unlikely that starter motor drive teeth would damage engine flywheel teeth. A starter’s teeth are softer and lighter, so they will always sustain more damage when the two clash.

- On older starter motors, it was common practice to give the body of a reluctant motor a few taps with a hammer to encourage it to start. On modern starters, ‘hammer hitting’ can cause catastrophic damage to the unit.

There are many variations on starter motors. Some look identical but have a different plug configuration. Certain starter motors have no nose cone, and these can usually replace a nose cone unit. There are also cases where starters with a different number of teeth can be fitted interchangeably.

Always cross-reference the old unit number from the original starter motor to make sure the correct replacement is being fitted.

DRIVE YOUR ROTATING ELECTRICS KNOW HOW

Do you have further queries? For in-person support, book a TechMate visit today! Contact the team on 01174 288090 or email [email protected]. All other technical support is available via our expert NAPA Technical Team on 03333 136597 or email [email protected].