Know How – Expert Edition – How Do Alternators Work?

15 Oct 2021

With MATT MASTERS

Resident NAPA expert Matt Masters makes his Expert Edition debut this issue to explain the ins and outs of the alternator. As one of the finely tuned mechanical minds working to keep the NAPA brand going strong, Matt has developed an in-depth understanding of a wide range of components. If you would like to learn more about alternators and other parts, contact the NAPA helpline at 03333 136597.

INTRODUCTION

It can be easy to take the parts we work with for granted. We all know alternators are extremely important in supplying the electrical current vehicles need to function. But how do they work? For a better understanding of the components within one of your most important internal components, look no further than NAPA Know How.

THE COMPONENTS

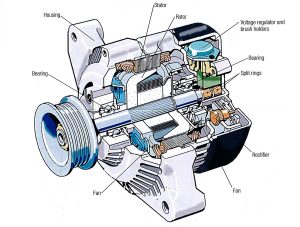

Alternators are named for their function – they generate alternating electrical current to charge the battery and power the vehicle’s electrical devices using the following key components:

The Pulley – Driven by the engine via a belt to provide rotational force to the rotor shaft.

The Pulley – Driven by the engine via a belt to provide rotational force to the rotor shaft.- The Rotor – Contains a coil of wire wrapped around a shaft for generating an electromagnetic field while rotating.

- The Stator – A stationary component containing multiple coils wound through a soft iron ring. Generates electrical charge by working in tandem with the rotor.

- The Rectifier – Situated at the back of the alternator, responsible for converting Alternating Current (AC) into Direct Current (DC).

- The Regulator – An integrated circuit that monitors voltage output and controls the charging process.

THE MECHANICS

The coiled wires in the rotor generate their electromagnetic field when a voltage is applied to both ends. This forces the electric current in the wiring to move in specific directions based on the electromagnetic pull in the stator. When the charge alternates between positive and negative directional flows, it creates an AC which is then transferred into a DC by the rectifier, as vehicle batteries can only be charged by DC. Rectifiers generally contain diodes that act as ‘electrical valves’.

The regulator often uses semiconductors to control the production of electricity based on engine speed, modulating the current to the rotor to vary the output voltage to suit the vehicle’s electrical demand.

DID YOU KNOW?

The coils in the stator use copper wires wound between slots in an iron ring to generate three “phases” of AC electricity when the rotor spins. Each phase is typically positioned 120° from the last for a constantly alternating current.

Become a NAPA Stockist Download PDF Guide