Know How – Expert Edition – How Do Starter Motors Work?

10 Nov 2021

With MATT MASTERS

Matt Masters returns for another Expert Edition piece on the ins and outs of starter motors. With his encyclopedia of NAPA Know How at his disposal, Matt is perfectly suited to giving a crash course on all things rotating electrics. If you would like to learn more about starter motors and other parts from the rest of the technical team, however, you can contact the NAPA helpline at 03333 136597.

INTRODUCTION

Once upon a time, starting a car engine required you to physically turn it over from outside the vehicle, which could lead to serious injuries if done incorrectly. The starter motor allows you to turn the engine over from the comfort of the cabin with relative ease, but understanding the mechanics behind this process may need a little NAPA Know How.

THE COMPONENTS

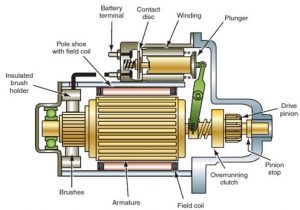

There are a few key components that make up a starter motor and are responsible for working together to successfully turn an engine over:

- The Solenoid – A wire coil that generates an electric field when powered by the ignition key, pulling the plunger back and pushing the drive pinion forward.

- The Drive Pinion – A gear responsible for meshing with a corresponding gear on the engine’s flywheel to turn it.

- The Plunger – A mechanism that gets pulled into the solenoid’s electromagnet, moving the contact disc and creating a circuit to spin the motor. It also pushes the drive pinion into the flywheel.

- The Signal (S) Terminal – An input connected to the ignition switch. It powers the solenoid on and off when the switch is in the start position.

THE MECHANICS

The drive pinion engages with the flywheel teeth and is turned by the solenoid-powered electric motor in the starter. When the pinion turns, so does the much larger flywheel, amplifying the torque to turn the engine.

A heavy-duty switch is positioned at the end of the solenoid. When the ignition key is turned and the S terminal powers the solenoid, the plunger and contact disc are pulled into the contacts to connect the heavy current from the vehicle’s battery to the starter.

In starters with pre-engagement systems, the plunger pushes the piston early, causing it to move into its mesh with the flywheel before the motor is turned on to reduce the chance of misalignment.

DID YOU KNOW?

Starter motors only engage with the engine long enough to turn it over. If a starter were to stay engaged past this point, the engine would spin it at a speed of 40,000 RPM.